The

Mars Exploration Rovers consists of twin probes

that are controllable rovers that move freely on the

surface of Mars. The rovers are:

- Spirit (MER-A)

- Opportunity (MER-B)

Spirit was launched on June 10, 2003 at 1:58 PM EST (Pad 17-A) and

landed on Mars on January 3, 2004. The Spirit

rover carries a memorial plaque dedicated to the

crew of the

Space Shuttle Columbia - the loss of the

Space Shuttle on February 2, 1003.

Opportunity was launched on July 7, 2003 at 11:18 PM EST (Pad 17-B) and

landed on Mars on January 24, 2004.

Both were launched from the Delta II rocket which was also responsible for launching all Mars related missions: Mars Global Surveyor in 1996, Mars Pathfinder in 1996, Mars Climate Orbiter in 1998, Mars Polar Lander in 1999, Mars Odyssey in 2001, and Mars Phoenix in 2007.

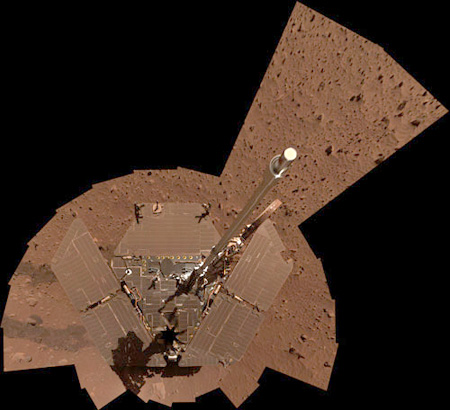

The tall object on the probe is the "pan-cam"

and is designed to be the height of an "average"

human so the proper perspective can be achieved.

Additionally, the wing like structure are the

solar panels, used to recharge the batteries.

While the mission was only expected to last a

few months, both probes are still operating!

The image above shows a self portrait by the

Spirit rover. The purpose of the rovers are to

examine closely the chemical makeup of the rocks

and soil. Special instruments on the rovers

include spectrometers and a rock cutting tools.

While the data is still being collected and

analyzed, the results are wonderful - water did

exist at some point on the Martian surface.

Week in Review slideshow of MER discoveries:

2004:

2005:

One Year Anniversary Slide Show

Some of the equipment used on the rovers are:

Alpha-Particle X-Ray Spectrometer

(from the MER Datasheets):

The Athena Alpha Particle X-ray

Spectrometer works by exposing martian materials

to energetic alpha particles and x rays from a

radioactive

244Cm

source, and then measuring the energy spectra of

backscattered alphas and emitted x rays. The

instrument is conceptually similar to the APXS

instrument that flew on the Mars Pathfinder

mission. However, there are several differences

that improve the instrumentÃs reliability and

performance. Unlike the Pathfinder APXS, the

Athena APXS does not have a proton mode. The

proton mode has been dropped because recent

increases in the spectral resolution and

sensitivity of the x-ray mode have made it

unnecessary. Significant modifications have also

been made to the instrument to reduce the CO2-induced

background that was observed on Pathfinder, to

improve x-ray spectral resolution, and to

decrease susceptibility to electromagnetic

interference. In addition, the Athena APXS will

undergo extensive preflight calibration under

Mars-ambient conditions, and will have two

onboard reference targets for postlanding

calibration on Mars.

The APXS instrument consists of

a sensor head mounted on the roverÃs Instrument Deployment Device, and electronics mounted in

the roverÃs Warm Electronics Box.

The sensor head contains six

244Cm

alpha radioactive sources with a total source

strength of about 30 mCi. The sources are each

covered with 3-μm aluminum foils that reduce the

energy of emitted alpha particles from the

initial value of 5.8 MeV to about 5.2 MeV. At

this energy, the alpha particle scattering cross

section of carbon is significantly reduced. The

reduction is accompanied by a slight degradation

of the alpha spectral resolution caused by

broadening of the excitation spectrum, but the

net result is a significant suppression of

atmospheric background in the alpha spectra.

Collimators in front of the sources define the

instrumentÃs field of view, which is about 38 mm

in diameter at the nominal working distance of

29 mm.

Surrounding the sources are six

thin alpha detectors. The FWHM for the alpha

mode of a

244Cm

peak at 5.8 MeV is less than 100 keV. Interior

to the ring of sources is a single

high-resolution silicon drift x-ray detector

with a 5-μm beryllium entrance window. The FWHM

of this detector at 6.4 keV is about 160 eV,

compared to 260 eV for the Pathfinder APXS. The

noise level in the x-ray mode will be less than

600 eV at temperatures below ñ30∞C, and the

efficiency at the 1.24 keV line of Mg will be at

least 20%.

Preamplifiers for both detector

channels and a circuit to generate detector bias

voltages are also mounted on the sensor head,

significantly reducing the instrumentÃs

susceptibility to electromagnetic interference.

The entrance to the detector

head is normally protected from martian dust and

other potential contaminants by a pair of doors.

These doors swing inward and lock open when the

sensor head is pressed against a target or other

hard surface. They can be closed again by

actuation of a release mechanism. The inner

surfaces of the doors provide a calibration

reference surface for the instrument. The sensor

head can also, if desired, be brought into

contact with the magnetite rich calibration

target designed for the Mˆssbauer spectrometer.

Signals from both detector channels

are processed by electronics mounted in the rover

WEB. Alpha signals from charge-sensitive

preamplifiers ñand similarly-x ray signals from a

customized voltage-sensitive preamplifiers in the

sensor head ñare further amplified and filtered

(semi-Gaussian pulse shapes) and then routed to peak

detectors, a multiplexer, and into a 16-bit A/D

converter for digitization. Signals from comparators

that trigger if signals exceed a preset level

initiate a sequence of logic signals necessary for

peak detection (sample gate and signal hold) and the

conversion process (program interrupt, alpha/x-ray

flags). A microcontroller selects the appropriate

input to the multiplexer and controls

analog-to-digital conversion. The analyzed events

are stored in the microprocessor buffer memory,

building up alpha- and x ray spectra.

The rover can place the APXS sensor

head in contact with rock surfaces or soil surfaces

at inclinations within the range of 0 to 90∞. Under

normal conditions, it should be possible to position

the instrument centerline within 0.4 cm of a target

location that has been observed by another IDD

instrument.

Proper preflight calibration is

essential to analysis of APXS data, so the Athena

APXS will undergo an extensive calibration program.

All calibration measurements will be made in a

chamber filled with a mixture of gases that closely

matches the composition of the martian atmosphere,

at the appropriate atmospheric density. Calibration

measurements will include:

-

spectral ìlibraryî

measurements of pure elements and oxides;

-

geochemical standards

that span the full range of plausible martian

surface compositions;

-

standard targets under

a range of atmospheric densities and measurement

geometries;

-

standard targets in

both natural and powdered form, to investigate

texture effects;

-

the APXS flight

calibration target;

-

the magnets of the

magnet array;

-

several blind certified

geochemical reference standards, for independent

assessment of the accuracy with which compositions

can be measured.

All of these measurements will be

made using the flight radiation sources.

The accumulation time for the APXS

will typically be at least 10 hours per sample

analysis, although significantly shorter durations

are possible when only the x-ray mode is used. Most

data accumulation will take place during the night

when the ambient martian temperature is the lowest,

giving the best energy resolution on all spectra.

However, it is desirable to break the total

accumulation time into several shorter accumulation

periods. The APXS can store up to 12 sets of

accumulated spectra and can transmit the data to the

rover either after each accumulation period, or all

sets of spectra at the end of the final accumulation

period.

The x-ray mode is sensitive to major

elements, such as Mg, Al, Si, K, Ca, and Fe, and to

minor elements, including Na, P, S, Cl, Ti, Cr, and

Mn. The alpha mode is sensitive to lighter elements,

particularly C and O. The depth of analysis varies

with atomic number, ranging from approximately 10 to

20 micrometers for sodium, to approximately 50 to

100 micrometers for iron. The detection limit is

typically 0.5 to 1 weight percent, depending on the

element. The APXS is insensitive to small variations

of the geometry of the sample surface because all

major and minor elements are determined, and can be

summed to 100 weight percent.

Back to Top

Microscopic Imager

(from the MER Datasheets):

The Athena Microscopic Imager (MI)

is a high-resolution imaging system mounted on the

IDD. The camera body is identical to the ones used

by Pancam, so the field of view is 1024 x 1024

pixels in size and the instrument has the same basic

radiometric performance characteristics as Pancam.

There is a single broad-band filter, so imaging with

the Microscopic Imager is monochromatic.

The MI optics employ a simple, fixed

focus design at f/15 that provides

3

mm depth-of-field at 30µm/pixel sampling. The field

of view is therefore 31â—Š31

mm at the working distance. The focal length is 20

mm, and the working distance is 63 mm from the front

of the lens barrel to the object plane. The

object-to-image distance is 100 mm. Preflight

geometric calibration will thoroughly characterize

the geometric distortion of the system.

The spectral bandpass of the MI

optical system is 400-680 nm. At best focus, the

modulation transfer function of the optics is at

least 0.35 at 30 lp/mm over this bandpass.

Radiometric calibration of the Microscopic Imager

will be performed with a relative (pixel-to-pixel)

accuracy of ≤5%,

and an absolute accuracy of

≤20%.

Calibration measurements will be obtained every 10

nm over the instrument's full spectral bandpass. The

MI signal to noise ratio will be at least 100 for

exposures of 20% full well over the spectral

bandpass and within the calibrated operating

temperature range (-55 to +5∫ C).

No onboard radiometric calibration

target is provided for inflight calibration of the

MI. It is likely that the MI will be able to view

the Compositional Calibration Target, and that this

target will provide fiducial marks that can be use

to perform a focus check. The MI will be able to

acquire unfocussed images of the martian sky,

providing flat fields.

The MI will be mounted on the

Instrument Deployment Device (IDD), allowing it to

be placed against surfaces that can also be examined

by the other Athena instruments. The IDD will have a

minimum controllable motion along a science target's

surface normal vector of 2}1

mm RMS, allowing it to image a rough surface in a

sequence of images. After placing the MI in position

for imaging, the motion of the IDD damps down to an

amplitude of less than 30 microns (i.e.,

less than one MI pixel) within 15 seconds. Whenever

the MI is not in use, the MI optics are protected

from contamination by a transparent cover. Preflight

calibration imaging will establish the transmission

properties of the cover. The cover is opened only

for MI imaging sequences. A contact sensor attached

to the MI will be used to detect rock and other hard

surfaces, to help ensure accurate positioning and

protect the MI from accidental damage.

The MI acquires images using only

solar or skylight illumination of the target

surface. Stereoscopic observations and mosaics can

be obtained by moving the MI between successive

frames. Stereo images and images taken at various

distances from the target will be used to derive the

3-dimensional character of the target surface.

Optical sections will also be combined to produce an

image of the target that is well-focused across the

entire frame.

Back to Top

Mini Thermal Emission Spectrometer

(from the MER Datasheets):

Mini-TES is a Michelson

interferometer that provides a spectral resolution

of 10 cm-1 over the wavelength range from 5-29 µm

(2000 - 345 cm-1). The instrument is mounted inside

the rover, and views the terrain around the rover by

using the PMA as a periscope. A scan mirror assembly

atop the PMA reflects radiation down through the PMA

and into the telescope and interferometer. The scan

mirror assembly allows Mini-TES to provide spectral

image cubes over a 360∞ range in azimuth and from

50∞ to +30∞ in elevation. The scan mirror assembly

also provides a view of internal and external,

full-aperture calibration targets. The elevation

mirror can be slewed to a stowed position in which a

cover blocks the Mini-TES aperture in the PMA,

protecting the optics from dust accumulation.

Mini-TES has two spatial resolution

modes. A solenoid-activated field stop can be

removed from the optical path to provide an IFOV of

20 mrad, or inserted to provide an IFOV of 8 mrad.

Baffles in the PMA define the stray energy field of

view and are designed to minimize stray energy from

outside the 20 mrad IFOV from entering the

interferometer. The inside of the PMA is designed to

minimize the stray background energy from the PMA

itself.

During data acquisition, the

PMAs elevation mirror and azimuth actuator are

sequenced to generate a raster image of the

scene. The scan mirror assembly can also be

commanded to allow Mini-TES to view the internal

and external calibration targets regularly in

order

to maintain instrument calibration during an

image acquisition. The elevation and azimuth

servos move and settle to each commanded

position ±1 mrad. Elevation steps of up to 20

mrad in size take place within the 200 msec

retrace period of the Mini-TES interferometer,

while azimuth steps may take as long as 1

second. Slews to the calibration targets take

significantly longer.

The Mini-TES telescope at the base

of the PMA is a reflecting Cassegrain configuration

with a mirror diameter of 6.35 cm, a focal ratio of

f/12, and an intermediate field stop that feeds an

approximately collimated beam into the Mini-TES

interferometer. The 6.35-cm telescope diameter

defines the minimum size of the Mini-TES beam; the

beam diverges further at an angle of either 8 or 20

mrad, depending on the resolution mode chosen. The

optical design provides for more than 85% of the

encircled energy to be contained in an

area equal to a single IFOV, 98% within an area

equal to 2 â—Š 2 IFOV, and 99.8% within an area equal

to 3 â—Š 3 IFOV. Focus is maintained from 2 meters to

infinity, with a blur of no more than 15% of an IFOV

at infinity focus.

The Mini-TES Michelson

interferometer uses the same flexure-mounted linear

motor mechanism and drive electronics as the Mars

Observer (MO)/Mars Global Surveyor (MGS) TES

instrument. The system uses a 980-nm interferometer

to generate interference fringes that control the

linear drive servo and time the acquisition of the

IR spectrometer data samples. The design is

simplified from the TES by combining the

infrared and visible counting interferometers into

one interferometer at one end of the motor drive and

replacing neon bulbs with redundant laser diodes.

Double-sided interferograms at a spectral resolution

of 10 cm-1 are obtained with a mirror travel

distance of 0.55 mm in 1.8 sec. A voltage ramp is

used to drive the mirror at a fixed velocity, and

position feedback is obtained from a linear voltage

displacement transducer. Optical switches sense

beginning of scan and synchronize the interferometer

with the elevation and azimuth drive motors.

Mini-TES uses a single uncooled

deuterated triglycine sulfate pyroelectric detector

sized to define the instruments 20-mrad IFOV. The

IFOV, dwell time, and interferometer scan rate have

been selected to produce frequencies in the range of

15 to 120 Hz which is

the range over which minimum noise equivalent

spectral radiance (NESR) can be achieved. The

detector provides the necessary performance over a

temperature range from 10 to +20∞C and with reduced

performance from 40 to +35∞C.

The NESR of the Mini-TES for a

single spectral accumulation interval at 10 µm

observing a scene at 270 K and 20 mrad will be <1.25

â—Š 10-8 W cm-2 sec-1 sr-1, corresponding to a

signal-to-noise ratio (SNR) of at least 450 for

co-addition of two observations. Radiometric

calibration of Mini-TES over its full spectral range

will be performed with an absolute accuracy of 5% or

better and a relative precision (pixel-to -pixel) of

2% or better, viewing a 270 K blackbody. The

internal calibration target is located inside the

head of the PMA, and the external target is located

on the deck of the rover. Both targets have

V-grooved surfaces and are coated with high

emissivity paint. Temperature sensors affixed to

both targets have an absolute accuracy of ±0.2∞C and

a precision of ±0.1∞C.

The instruments electronics are

based on the electronics of the MO/MGS TES. A 14.515

MHz internally-generated clock signal provides the

control timing for the interferometer motor

controller and synchronizes the scan timing and data

collection events with the

rover computer. Detection of start of scan by the

optical switches also signals to the rover computer

that data collection has begun. This signal triggers

an internal timer that initiates retrace of the

interferometer mirror after 1.8 seconds. Signals

from the detector

are fed through a pre-amplifier, variable gain

post-amplifiers for each field of view, an analog

multiplexer, a 16-bit A/D converter, and into an

output buffer.

Mini-TES begins collecting data at

the application of power. The instrument acquires

data in a cyclic fashion, with a period of two

seconds corresponding to the Michelson mirror scan

followed by its retrace. Spectral integration is

coordinated with the PMA elevation and azimuth drive

mechanisms using the rover computer. On each

two-second period (known as one ICK), the hardware

fills up the Mini-TES data buffer with header data,

interferogram data from the selected spectrometer

field of view, and the telemetry data.

Mini-TES flight software controls

the transfer of the data from the Mini-TES data

buffer to the rover CPU memory. Once the Mini-TES

data is available in the rover memory, the flight

software performs a Fourier transform on the

interferogram in order to generate a spectrum. It

then performs data aggregation in order to reduce

the total volume of data to be downlinked. Separate

programmable data aggregation modes in the spatial

domain (averaging spectra from consecutive ICKs) or

in the spectral domain (averaging data from

contiguous spectral points) are available. Data

volume is further reduced via lossless compression

using a Rice algorithm. Compressed data then

undergoes final formatting, packetization, and

transfer of the packets to rover data storage for

downlink.

The rover computer issues commands

to PMA motor driver circuitry in order to

synchronize the mirror movements to the Mini-TES

data acquisition. Direct commands from the rover

computer control instrument power and selectable

gain state, field of view, motor on/off, laser

heater on/off, redundant start-of-scan optical

switches, and redundant laser diodes.

Mini-TES operates primarily during

mid-day (10 a.m. to 3 p.m. local time) to obtain

high-quality spectral measurements of emitted

infrared energy. Nighttime observations may be

obtained to measure surface and atmospheric

temperatures of the full diurnal cycle for

thermophysical and boundary layer studies.

Back to Top

Mossbauer Spectrometer

(from the MER Datasheets):

The Athena Mˆssbauer spectrometer

uses a vibrationally-modulated 57Co source to

illuminate target materials. Backscattered gamma

signals are binned according to the source velocity,

revealing hyperfine splitting of 57Fe nuclear levels

that provides mineralogical information about the

target. The main parts of the instrument are the

Mˆssbauer drive that moves the 57Co source with a

well-known velocity, the γ- and x-ray detectors that

detect the backscattered radiation, the

microcontroller unit, the 57Co/Rh Mˆssbauer source,

and the radiation collimator and shielding.

The spectrometer is split into the

sensor head on the roverÃs Instrument Deployment

Device (IDD), and the electronics in the warm

electronics box (WEB). The sensor head carries the

Mˆssbauer drive with the analog part of the drive

control unit, the 57Co/Rh Mˆssbauer source, the

radiation collimator and shielding, the four PIN-

diode detector channels including pulse amplifiers,

and one reference detector channel to monitor the

velocity of the drive using a weak

57Co source and a well known Mˆssbauer reference

absorber in transmission geometry.

The WEB electronics consist of the

microcontroller and memories for data acquisition

and temporary storage. An extra FPGA logic unit

provides several functions for internal

communication, generates the velocity signal for the

drive, and contains fast pulse counters for

the detector signals. The WEB electronics also

contain voltage supply regulators and detector bias

voltage generators.

The analog signals of the five

detector channels are analyzed by discriminators for

14.4 keV and 6.4 keV peaks. Upper and lower

threshold values of the discriminators are generated

by digital to

analog converters (DACs). These values can be

changed automatically to follow the temperature

drift of the amplifiers. Digital signals from the

discriminators are sent to the velocitysynchronized

counters whenever a detected pulse is within the

specified range. Mˆssbauer spectra for the two

different energies of 6.4 keV and 14.41 keV are

sampled separately.

The Mˆssbauer spectrometer has its

own internal microcontroller, so that it can collect

data independently of the rover computer. Instrument

parameters are stored in a fault-tolerant fashion in

3 separate FRAMs and default values for these

parameters are taken from ROM in case of an error.

Every 60 minutes during a measurement, data is

stored into the EEPROM. In case of a failure of the

power supply, after restart of the instrument the

data acquisition will continue with this data. Each

Mˆssbauer spectrum consists of 512 ◊ 3-byte

integers. The pulses from the 4 counters are added

by hardware. Normally there is one spectrum for each

detector. The spectra are sampled into an SRAM of

128 Kbytes size.

Measurements are made by placing the

instrument directly against a rock or soil sample.

Physical contact is required to provide an optimal

measurement distance and to minimize possible

microphonics noise on the velocity-modulated energy

of the emitted γ rays. The mechanical construction

of the IDD and the interface limit vibration-induced

velocity noise at the sensor head to less than 0.1

mm/s. A contact plate is mounted at the front part

of the sensor head, assuring an optimal distance

from the sensor head to the sample of about 9 to 10

mm. A heavy metal collimator in front of the source

provides an irradiated spot of nominally 15 mm (up

to 20 mm, depending on actual sample distance and

shape) in diameter on the surface of the sample. The

IDD can position the instrument with an accuracy of

0.4 cm or better with respect to the position

observed by other IDD-mounted instruments. The

average depth of sampling by Mˆssbauer data is about

200 to 300 μm.

Mˆssbauer parameters are temperature

dependent. Especially for small particles exhibiting

superparamagnetic behavior (e.g., nanophase Fe

oxides), the Mˆssbauer spectrum may change

drastically with temperature. The observation of

such changes will help in determining the nature of

the iron-bearing phases. Therefore Mˆssbauer

measurements will be performed over a range of

diurnal temperatures spanning both the daytime

maxima and the nighttime minima.

One Mˆssbauer measurement takes

approximately 12 hours, depending on the phases

present in the sample and the total iron content.

The temperature variation for one spectral

accumulation interval will not be larger than about

±10∞C. When larger variations occur, spectra for

different temperature ranges are stored separately,

resulting in an increase in the total data volume

(depending on the number of temperature intervals

required), and a decrease of statistical quality

for the individual subspectra.

In parallel with the measurements of

samples, calibration spectra will be taken using the

reference channel implemented in the instrument. A

calibration target containing a thin slab of

magnetite-rich rock will also be included on the

rover where it can be viewed directly by the

instrument immediately after landing, as well as

later in the mission if necessary.

The performance of the Mˆssbauer

Spectrometer can be defined by measurements made in

transmission geometry with a Mˆssbauer source in

front of the instrument at a distance of 5 cm, and

in a backscattering geometry with the source

internal to the instrument in its flight

configuration. Instrument performance requirements

for such purposes are specified for a Mˆssbauer

source strength of 100 mCi for the backscattering

mode, 10ñ20 mCi for transmission mode, an

integration time of 10 minutes for the energy

spectra (backscattering and transmission), and an

integration time of 10 hours for the Mˆssbauer

backscattering spectrum.

(1) Specifications for the energy

spectra taken in transmission mode (see Figure 1) at

a temperature of +20 (±1)∞C are:

-

noise level: The intensity at

(A) (channel 11) will not exceed 20.000 (±1000)

counts;

-

at (B) (ìvalleyî, channel 15),

the intensity will be less than 8900 (±500)

counts; and

-

the peak-to-valley ratio (ratio

of intensities at (C) (channel 19) and (B)) will

be equal to

or larger than 1.5.

(2) Specifications for the energy

spectra taken in backscattering mode (see Figure 2)

at a temperature of +20 (±1)∞C are:

-

noise level: The intensity at

(A) (channel 18) will not exceed (50 ±10)

counts;

-

at (B) (channel 36) the

intensity will be less than 23 ±5 counts;

-

within the energy range channel

25 to channel 50 the intensity will be between 2

and 25 counts; and

-

at (C) (channel 145) the

tantalum X-ray line generated in the collimator

will be visible; the intensity will be 18 ±4

counts.

(3) Specifications for the Mossbauer

spectra taken in backscattering mode (bottom figure)

on its magnetite-rich calibration target at a

temperature of +20 (+/-1) degrees Celsius are that:

-

the peak/background ratio will

not be less than 1.11, as shown in Figure 3; for

a source activity between 80 and 120 mCi; and

-

the magnetite signal will be

visible with a peak/background ratio of not less

than 1.005.

Back to Top

Pancam

(from the MER Datasheets):

Pancam uses 1024â—Š2048 pixel Mitel

CCD array detectors developed for the MER Project.

The arrays are operated in frame transfer mode, with

one 1024â—Š1024-pixel region constituting the active

imaging area and the another adjacent 1024â—Š1024

region serving as a frame transfer buffer. The frame

transfer buffer has an opaque cover that prevents

>99% of light at all wavelengths from 400 to 1100 nm

from being detected by this region of the CCD. The

pixels are continuous, and the pitch is 12 μm in

both directions. The arrays are capable of exposure

times from 0 msec (to characterize the ìreadout

smearî signal acquired during the ~5 msec required

to transfer the image to the

frame transfer buffer) to 30 sec. Under expected

operating conditions, the arrays have at least

150,000 electrons of full-well depth, and a read

noise of less than 50 electrons. Dark current varies

with temperature; it is negligible at -55∞C and is

<1200 electrons/sec

at 0∞C. Analog to digital converters provide a

digital output with 12-bit encoding, and SNR > 200

at all signal levels above 20% of full scale. The

detector response has a linearity > 99% for signals

between 10% to 90% of full well.

Each array is combined with optics

and a small filter wheel to form one eye of a

multispectral, stereoscopic imaging system. The

optics for both cameras consist of identical

3-element symmetrical lenses with an effective focal

length of 38 mm and a focal ratio of f/20, yielding

an IFOV of 0.28 mrad/pixel and a square FOV of

16.8∞◊16.8∞ per eye. The optics and filters are

protected from direct exposure to the martian

environment by a sapphire window at the front of the

optics barrel. The optical design provides for more

than 90% of the encircled energy to be contained in

an area equal to 3â—Š3 IFOVs, and 99% in an area equal

to 5â—Š5 IFOVs, across the entire range of spectral

responsivity of the instrument and over the required

operating temperature range for performance of

Pancam within specifications (-55∞C to 0∞C). The

optical design allows Pancam to maintain optimal

focus from infinity to within about 1.5 meters of

the cameras. At ranges closer than 1.5 meters,

Pancam images suffer from some defocus blur. For

example, at a range of 80 cm (the approximate

distance from the Pancam calibration target), the

defocus blur is about 10 pixels.

Each filter wheel has eight

positions, allowing multispectral sky imaging and

surface mineralogic studies in the 400-1100 nm

wavelength region. The left wheel contains one clear

(empty) position. The remaining filter wheel

positions are filled with narrowband interference

filters that are circular and 10 mm in diameter, and

that have the central wavelengths and bandpasses

listed in Table 2.1.2-1. One filter on each eye has

an ND5.0 coating to allow direct imaging of the Sun

at two wavelengths.

Radiometric calibration of both

Pancam cameras will be performed with an absolute

accuracy of 7% or better and a relative precision

(pixel-to-pixel) of 1% or better. Calibration will

be achieved using a combination of preflight

calibration data and inflight images of a Pancam

calibration target carried by the rover. The Pancam

calibration target is placed within unobstructed

view of both camera heads and will be fully

illuminated by the Sun between at least 10:00 AM and

2:00 PM local solar time for nominal rover

orientations. The target has three gray regions of

variable reflectivity (approximately 20%, 40%, and

60%) and four colored regions (peak reflectance in

the blue, green, red, and near-IR) for colorimetric

calibration. It includes a vertical post that will

cast a shadow simultaneously across all three gray

surfaces at some time within the 10:00 AM to 2:00 PM

nominal operating range. The calibration target is

large enough that defocus

blur will not produce significant degradation of the

calibration images.

The two Pancam eyes are mounted on a

mast on the rover deck. The mast is referred to as

the Pancam Mast Assembly (PMA), and also includes

several key components for the Mini-TES. The PMA is

erected to the vertical position by a deployment

actuator at its base. The cameras are located on a

"camera barî with a boresight 180∞ from the Mini-TES

boresight. The rover navigation cameras (Navcams)

are also located on this same camera bar, and point

in the same direction as Pancam. The boresight of

the Pancam cameras is approximately 1.3 m above the

martian surface with the PMA in the deployed

position. The cameras are moved together by ±90∞ in

elevation using a geared brush

motor on the camera bar. The entire PMA head,

including the cameras, can be rotated 360∞ in

azimuth by a geared brush motor assembly. A separate

geared brush motor provides elevation actuation for

the Mini-TES elevation mirror assembly. Hard stops

are provided for all actuation axes.

The two Pancam eyes are separated by

30 cm horizontally and have a 1∞ toe-in. This

separation and toe-in provide an adequate

convergence distance for scientifically useful

stereo topographic and ranging solutions to be

obtained from the near-field (5-10 m) to

approximately 100 m from the rover. Pointing control

is <2∞ in azimuth and <1∞ in elevation. Pointing

knowledge relative to the hardstops is 0.1∞ over the

entire range of motion of Pancam.

Pancam will operate primarily during

the daytime to obtain high-quality measurements of

sunlight reflected off rock and soil surfaces and

airborne dust particles, as well as direct solar

images using the two ND filters. Twilight or

nighttime sky or astronomical object imaging may be

possible but has not been committed to by the

Project. The required

operating temperature range for performance of

Pancam within specifications is -55∞C to 0∞C.

Pancam will be commanded by and will

return digital data directly to the rover computer.

The computer provides the capability to perform a

limited set of image processing tasks

on Pancam data prior to transmission. These tasks

include (1) bias and dark current subtraction, (2)

electronic shutter effect correction, (3) bad pixel

replacement, (4) rudimentary automatic exposure

control capability to maximize the SNR of downlinked

data while preventing data saturation, (5) image

subsampling and subframing, and (6)

image compression using a JPL-developed wavelet

compression algorithm called ICER.

Pancam telemetry is collected by the

rover computer and downlinked according to an

overall priority queue scheme agreed upon in advance

by the MER Science Operations Working Group. Image

data are packetized, with each packet containing

sufficient information to allow receipt in any order

and to allow incremental image reconstruction

even in the event of typical transmission errors and

packet losses.

Back to Top

Rock Abrasion Tool

(from the MER Datasheets):

The Rock Abrasion Tool (RAT) will be

used to penetrate through dust and surface

alteration that might be present on rocks, exposing

materials more likely to preserve evidence of

environmental

conditions at the time of their formation. The fresh

surfaces exposed can then be characterized by all of

the Athena instruments. The RAT is a diamond-tipped

grinding tool capable of removing a cylindrical area

4.5 cm in diameter and at least 0.5 cm deep from the

outer surface of a rock. This operation takes about

2 hours for a dense basalt.

The RAT has a total of three

actuators (see figure). One causes each of two

grinding wheels to rotate at high speeds. Each of

these grinding wheels has two teeth, which cut out a

circular area associated with each grinding head as

the head rotates. A second actuator causes the two

grinding wheels to revolve around one another at a

much slower rate, sweeping the two circular cutting

areas around the full 4.5-cm diameter cutting

region. Finally, a third ìz-axisî actuator

translates the entire cutting head toward the rock,

causing it to penetrate to the commanded depth.

In order to grind a rock, the IDD

places the RAT directly against it. Contact is made

on two small spikes external to the grinding heads,

and a ring surrounding the heads can adjust in two

orthogonal axes to the orientation of the rock

surface. Once pressed firmly against the rock by the

IDD, all further actuations take place within the

RAT itself. Rotation and revolution of the grinding

wheels is initiated, and they are slowly translated

toward the rock surface by the z-axis actuator until

contact is made. Encoders monitor penetration

progress, and allow closed-loopcontrol of the

grinding process. A dust skirt around the cutting

surfaces helps to prevent release of dust that might

contaminate instruments.

The RAT is designed to preserve

petrologic textures of the prepared rock surfaces as

fully as possible, so that they can be viewed

effectively using the MI. The grinding process is

slow enough that no measurable modification of rock

chemistry or mineralogy by frictional heating is

anticipated. The grinding wheels are designed so

that contamination of the exposed surface by

cuttings from the rock (and previous rocks) is

minimized. Grinding wheel materials are selected

so that there should be no detectable contamination

of rock surfaces due to wear of the grinding heads

themselves.

During the operation of the RAT, the

rover will monitor currents, temperatures, and

encoder readouts for all three RAT actuators. These

data can be used to infer information about the

strength properties of the rocks that have undergone

grinding. A pre-flight test program is planned to

establish some of the relationships among these

parameters and rock strength, but this program will

be limited in scope. Further post-launch testing

with an engineering model or flight spare RAT is

possible.

Since the mission is still on-going, up to date

information will be available from the

Mars Exploration Rovers website.

Back to Top |